Products

Our Products

Cotting Industries offers complete Hydrogen Gas Production Plants using its patented Double-Tube™ reformer for hydrogen generation and Pressure Swing Adsorption for hydrogen purification. Double-Tube™ reformers and Pressure Swing Adsorption systems may be purchased separately.

Hydro-Mini® Hydrogen Gas Production Plants

Hydro-Mini® Hydrogen Gas Production Plants

Benefits

The Hydro-Mini® is a pre-engineered hydrogen plant product line that achieves superior economic performance by combining proven process technology with innovative component design and modular plant packaging. The Hydro-Mini® allows hydrogen gas to be produced more reliably and cost effectively than any other small-scale hydrogen plant by:

- reducing capital investment;

- lowering operating cost;

- operating efficiently across a wide production range;

- setting new standards for safety and reliability;

- simplifying plant installation and operation;

- enabling low cost relocation to new sites; and

- providing for fully automated startup/shutdown, unattended operation and remote plant monitoring.

Additionally, the Hydro-Mini®:

- eliminates availability concerns of compressed gaseous or cryogenic liquid hydrogen;

- provides an uninterrupted supply of hydrogen in regions with limited distribution infrastructure; and

- provides long-term hydrogen cost savings.

Features

The Hydro-Mini® product line consists of three plants with nominal capacities of 3,750 scfh, 7,500 scfh and 15,000 scfh. Each plant incorporates the following unique design features:

The Hydro-Mini® product line consists of three plants with nominal capacities of 3,750 scfh, 7,500 scfh and 15,000 scfh. Each plant incorporates the following unique design features:

- Compact, simple and efficient proprietary Double-Tube™ reformer for hydrogen production.

- Fully integrated waste heat boiler for steam production.

- Feed gas desulfurizer for long catalyst life.

- Water-gas shift reactor for maximum hydrogen yield.

- Four-vessel pressure swing adsorption system for hydrogen purification.

- Factory installed process control system, instruments, light fixtures, and plug-and-play electrical wiring system for easy installation.

- Single point utility connections for convenient site tie-in.

- Automatic emergency shutdown system for maximum safety.

- 100% factory assembled on a single portable steel skid for high quality, fast delivery and quick installation.

- Capable of processing multiple feedstocks including natural gas, biogas, propane, LPG, and naphtha.

- Designed to meet the codes and regulations required for installation in North America, Europe, China, and Japan.

Process Description

Process Description

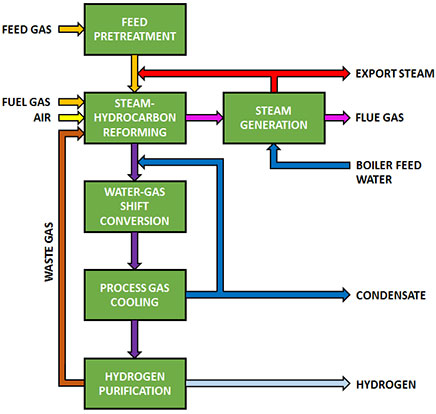

The process flow begins with a hydrocarbon feed gas entering the plant where it is preheated and sulfur compounds are removed via zinc oxide desulfurization. The sulfur free gas is mixed with saturated steam and further preheated before entering the reformer.

In the reformer, the steam/hydrocarbon mixture is converted to hydrogen and carbon monoxide at high temperature in the presence of a solid catalyst.

The hot reformed gas from the reformer is quenched with water and passed through the high temperature shift converter where steam and carbon monoxide are converted to additional hydrogen and carbon dioxide.

The process gas is cooled and then purified in the pressure swing adsorption system. Waste gas from the pressure swing adsorption system is burned as fuel in the reformer. The hot flue gas from the reformer is used to generate the steam required by the process and additional steam for export.

Patented Double-Tube™ Reformer

The Hydro-Mini® product line uses our proprietary Double-Tube™ reformer for hydrogen generation. The Double-Tube™ reformer is a novel design that combines high reliability and high thermal efficiency. This unique steam-hydrocarbon reformer is a compact furnace enclosure ideally suited for hydrogen production in the range 1,875 - 15,000 scfh.

The reformer contains a single reaction tube fired on two sides from the bottom. The furnace enclosure is wide at the bottom to accommodate the burners and tapered at a height several feet above the length of the flames to a narrow upper section. The reaction tube consists of an annular portion filled with catalyst and a center return tube. The reaction tube is supported from the bottom and allowed to thermally expand upward through the use of a counterweight system attached at the top of the tube.

The combination of the furnace enclosure geometry and the reaction tube with a center return tube results in an even temperature profile over the length of the reaction tube and a high thermal efficiency in the furnace.

Pressure Swing Adsorption (PSA) System

Pressure Swing Adsorption (PSA) System

The Hydro-Mini® product line uses PSA technology for hydrogen purification. The system is proven, cost effective and provides excellent hydrogen purity and yield.

The complete PSA system includes adsoption vessels filled with solid adsorbents, stepping valves, automatic isolation valves, a pressurization gas flow control valve, and a hydrogen product pressure control valve. The Hydro-Mini® process control system controls the PSA stepping sequence.

For more information, please contact us.